Over five days in March 2021, DTU Physics and DTU Compute have scanned the skull of the T. rex called Casper.

Both a surface scan (optical scan) of the skull's exterior with light and camera as well as a CT scan in micrometer resolution have been performed, which in addition to the surface scan depicts the skull's internal structure. The two scans have subsequently been put together so that you have both color and texture on the digital 3D scanning model.

DTU uses mathematical models to convert CT measurements into 3D models, convert the optical scans into 3D images and process the 3D images (data) for information.

DTU Physical and DTU Compute collaborate with the Natural History Museum of Denmark both surface scanning and scanning in a micro-CT scanner in the laboratories at DTU in Lyngby, where the 3D Imaging Center (3DIM) is located. Read more about the research project in the article: DTU 3D scans dinosaur skull

3DIM - 3D Imaging Center - is a collaboration between DTU Mechanics, DTU Wind Energy, DTU Energy, DTU Physics, and DTU Compute.

3DIM works with neutron and X-ray radiation. The center is part of DTU's strategic structure in relation to the use of the research facilities MAX IV and ESS - The European Spallation Source - in Lund in Sweden, as well as the DTU-based national research facility DANFIX in Lyngby with laboratories equipped with CT scanners. The regional image analysis center QIM is also part of 3DIM.

The CT scan

The micro CT scanners are similar to hospital scanners, where you shine through a material with X-rays, so you can see the internal structures in materials, such as bones.

The micro-CT scanners in DTU's laboratories are 2 meters high, 3 meters long, and 1 meter wide. They are equipped with an X-ray source that transmits the X-rays to the sample and a camera on the other side of the sample to record the X-rays coming through to produce radiographs.

In a micro-CT scanner, the sample is placed on a turntable so that images can be recorded from all angles when the sample is rotated 360 degrees.

CT scans provide a detailed description of the internal structures of the subject being scanned. This means that, for example, in the case of Casper, you can see which parts are fossil and which parts are artificial. About 60 percent of the skull is original material. In the scanners at DTU, you can see details down to 1 µm (micrometers), but also items that are up to 50 cm.

The recording of images in the CT scanners takes between 15 minutes and 24 hours.

Before the fossil entered the micro-CT scanner, the samples were put into boxes and stabilized. Here is Abdi Hedayat, Curator at the Natural History Museum of Denmark, in progress.

Here, one of the lower jaws is placed in the micro-CT scanner.

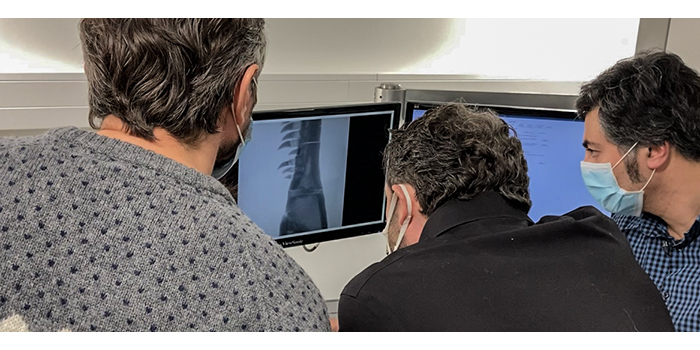

The researchers immediately check if the location is correct inside the turntable, so that everything is included in the scan.

Here the Natural History Museum films into the micro-CT scanner. Carsten Gundlach, Senior Research Engineer and head of the laboratories at the 3D Image Center, stands with a visor behind the computer screen.

Every single mineral in the skull is transformed into cancellous bone tissue so that the bone structure is preserved in the fossil.

The 3D geometry of the surface scan

During the surface scan, the skull of Casper is placed in a large box lined with light-absorbed felt, which means that you do not get glare when you illuminate the fossil with the projector. Here, Abdi Hedayat, Curator at the Natural History Museum, corrects the fossil.

Before scanning, calibrate the setup using a chessboard, from which you record images from different angles. In addition, the chessboard is illuminated with a pattern from the projector. Based on the checkerboard pattern and the pattern from the projector, it is possible to calculate exactly where the cameras and the projector are when scanning the correct object. When you see the same point on the surface of the skull from both cameras, you can calculate exactly where it is in the 3D image.

The projector is located midway between two cameras that record images. The cameras act like two eyes used to determine the distance to the surface of the skull (triangulation). Here, postdoc Morten Hannemose is working on the setting with cameras, while postdoc Janus Nørtoft Jensen below checks the output on the computer screen.

The scanning of the object gives a point cloud that consists of many millions of points that are not connected. Afterward, a surface construction is made using algorithms that connect the points to a continuous surface without holes.

The surface scan itself takes maybe five minutes, and in total it takes less than an hour because all algorithms are implemented efficiently in the computers.

In addition to the 3D geometry, you get color information from the cameras, which can be placed on top of the 3D points and transferred to the 3D reconstruction.

The coloring also requires modeling. The color changes depending on the angle you see it from, partly because the light is more or less reflected and can be scattered below the surface. So through the scan, several different color information about each pixel has been collected. Here you get the help of models that take into account how the light interacts with the object. So if the light comes from one direction, the object has a certain color. But if the light comes from a different direction, it has a different color.

DTU has also 3D-printed a lower jaw, which the Natural History Museum has shown at TV2 and DR on 21 April 2021. Below is the 3D-printed without paint. The museum painted the model itself.

Watch the two videos in the link below the contacts. NOTE: The videos open in a new browser on YouTube.